Casting khoompuab cov khoom zoo li aLub puab tsaig Crusher Tshuab or Gyratory Crusher. Lawv pab tsim txhua yam los ntawmCone Crusher Partsrau aManganese Steel Rauj. Qhov kev xaiv yog qhov tseem ceeb. Tshawb xyuas lub rooj no los ntawm cov chaw tsim khoom sab saum toj European:

| Txhua xyoo cam khwb cia hlau tso zis | 23,000 tons |

| Tus nqi tsis zoo | 5–7% |

Cov ntaub ntawv tshawb fawb suav nrog hlau, ceramics, polymers, thiab composites. Paub txog cov khoom siv casting zoo yuav pab engineers boost zoo thiab txiav pov tseg.

Ntsiab Cai

- Xaiv cov khoom siv casting zoo, xws li hlau, hlau,aluminium, los yog yas, ncaj qha cuam tshuam cov khoom zoo, nqi, thiab kev ua tau zoo.

- Cov ntaub ntawv ferrous muaj hlau thiab muaj zog tab sis tuaj yeem xeb, thaum cov ntaub ntawv tsis-ferrous xws li txhuas thiab tooj liab tiv thaiv xeb thiab sib dua.

- Plastics thiab ceramics muab cov txiaj ntsig tshwj xeeb xws li kev tiv thaiv corrosion thiab kub kub, ua rau lawv zoo tagnrho rau kev siv tshwj xeeb.

Yam tseem ceeb ntawm Casting Materials

Ferrous Casting Khoom: Hlau thiab Hlau

Ferrous casting cov ntaub ntawv muaj xws li hlau thiab hlau. Cov hlau no muaj hlau ua lawv lub ntsiab. Lawv ua lub luag haujlwm loj hauv cov tshuab hnyav thiab kev tsim kho. Hlau thiab hlau muaj qhov sib txawv. Cov lus hauv qab no qhia seb lawv piv li cas:

| Khoom / Feature | Cast Iron | Hlau (nrog rau me me thiab carbon steels) |

|---|---|---|

| Cov ntsiab lus carbon | 2-4.5% | 0.16–2.1% |

| Mechanical Properties | Siab compressive zog; nkaws | Ductile; tensile zog sib txawv |

| Corrosion Resistance | Zoo dua nyob rau hauv cov pa phem | Corrodes sai dua |

| Machineability | Yooj yim (grey hlau); nyuaj (dawb hlau) | Zoo, sib txawv ntawm hom |

| Daim ntawv thov | Cav thaiv, nres rotors | Gears, springs, automotive qhov chaw |

Cov khoom siv hlau casting ua haujlwm zoo rau cov cav cav thiab cov twj tso kua mis.Cov khoom siv hlau castingfits iav, springs, thiab ntau lub tsheb qhov chaw. Txhua hom coj nws lub zog rau lub rooj.

Non-Ferrous Casting Khoom: Aluminium, Tooj, Magnesium, Zinc

Non-ferrous casting cov ntaub ntawv tsis muaj hlau ua lub ntsiab. Aluminium, tooj liab, magnesium, thiab zinc belongs rau pawg no. Cov hlau no sib zog dua hlau thiab hlau. Aluminium casting khoom yog nrov rau lub tsheb qhov chaw thiab lub dav hlau ncej. Cov khoom siv tooj liab ua haujlwm hauv cov khoom siv hluav taws xob vim nws ua hluav taws xob zoo. Magnesium thiab zinc casting cov ntaub ntawv pab ua qhov sib sib zog nqus rau cov khoom siv hluav taws xob thiab cov cuab yeej. Cov hlau tsis muaj hlau tiv thaiv xeb thiab muab lub zog zoo rau lawv qhov hnyav.

Lwm yam Casting Materials: Plastics thiab Ceramics

Qee cov khoom siv casting tsis yog hlau kiag li. Plastics thiab ceramics muab cov txiaj ntsig tshwj xeeb. Cov yas tuaj yeem tsim cov duab nyuaj thiab tiv thaiv corrosion. Ceramics sawv ntsug kom kub kub. Cov neeg Ancient siv cov khoom siv ceramic rau melting tooj liab. Niaj hnub nimno ceramics, zoo li nano-zirconia, qhia txawm tias kev ua tau zoo dua. Lawv muaj lub zog khoov siab, toughness, thiab khawb kuj. Cov ceramics pab ua nyias, muaj zog qhov chaw rau cov xov tooj thiab saib.

Plastics thiab ceramics qhib qhov rooj tshiab rau cov khoom siv casting, tshwj xeeb tshaj yog nyob rau qhov kub tsis kam lossis cov duab tshwj xeeb tseem ceeb.

Cov cuab yeej thiab kev siv cov khoom siv Casting

Hlau Casting Khoom

Hlau casting khoom sawv tawm rau nws lub zog hauv compression. Cov neeg feem ntau siv nws rau txhua kab, cav thaiv, thiab cov tshuab hnyav. Grey cam khwb cia hlau muaj cov pa roj carbon flakes, uas ua rau nws yooj yim rau tshuab tab sis kuj nkig. Dawb cam khwb cia hlau, nrog carbon li hlau carbide, muaj zog tensile zoo dua thiab malleability.

- Lub zog:

- Ua haujlwm hnyav hnyav.

- Zoo rau qhov chaw uas tsis khoov ntau.

- Tsis muaj zog:

- Brittle thiab tuaj yeem tawg hauv qhov nro.

- Yooj yim rau xeb, tshwj xeeb tshaj yog nyob rau hauv qhov chaw ntub dej.

Ntxiv cov khoom xws li silicon, npib tsib xee, lossis chromium tuaj yeem txhawb kev tiv thaiv corrosion thiab kav ntev. Kev pleev xim thiab tshuaj xyuas tsis tu ncua pab tiv thaiv xeb thiab ua kom cov hlau castings zoo.

Kev ntsuam xyuas qhia tau hais tias cov xuab zeb siv rau hauv cov hlau casting tuaj yeem ua kom muaj cua sov, tab sis qhov chaw tiav nyob ntawm cov xuab zeb qhov loj thiab cov duab. Qhov no cuam tshuam li cas du lossis ntxhib qhov khoom kawg xav tau.

Hlau Casting Khoom

Cov khoom siv hlau casting coj qhov sib xyaw ntawm lub zog, ductility, thiab toughness. Cov tib neeg xaiv cov hlau rau lub zog, lub caij nplooj ntoos hlav, thiab cov khoom siv tsheb vim nws tuaj yeem ua rau ob qho tib si nro thiab compression. Cov khoom ntawm steel hloov nrog sib txawv alloys thiab kev kho mob.

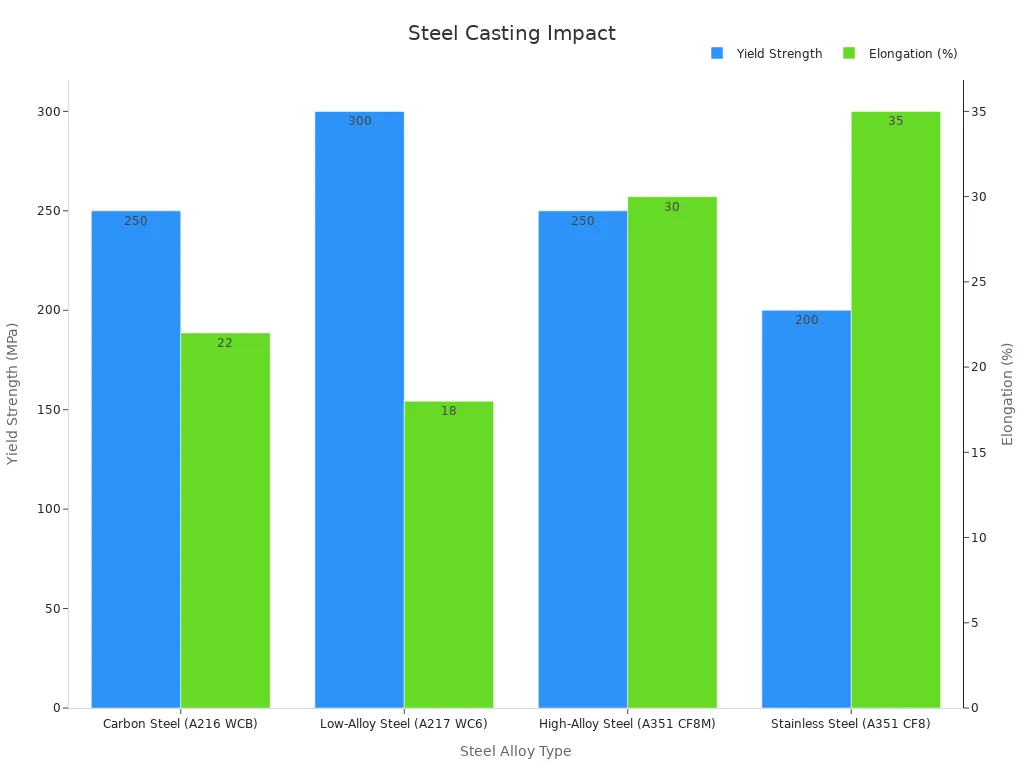

| Hlau Alloy Hom | Yield zog (MPa) | Tensile zog (MPa) | Elongation (%) | Corrosion Resistance |

|---|---|---|---|---|

| Carbon hlau (A216 WCB) | 250 | 450-650 | 22 | pluag |

| Cov hlau tsis tshua muaj hlau (A217 WC6) | 300 | 550-750 | 18 | Ncaj ncees |

| High-Alloy hlau (A351 CF8M) | 250 | 500-700 | 30 | Zoo heev |

| Stainless hlau (A351 CF8) | 200 | 450-650 | 35 | Zoo heev |

Steel qhov kev ua tau zoo nyob ntawm seb nws ua li cas. Kev ua kom txias sai dua ua rau cov nplej me me, uas ua rau cov hlau muaj zog dua. Kev kho cua sov thiab ua tib zoo casting txoj kev tuaj yeem txhim kho toughness thiab txo qhov tsis xws luag xws li pores.

Aluminium Casting Khoom

Aluminium casting khoom yog nrov rau nws lub teeb yuag thiab yooj. Nws yog feem ntau nyob rau hauv lub tsheb qhov chaw, lub dav hlau ncej, thiab electronics. Aluminium stands rau nws zoo zog-rau-qhov hnyav piv thiab zoo heev tiv thaiv xeb.

| Property/Aspect | Cast Aluminium | Cam khwb cia hlau | Grey Hlau |

|---|---|---|---|

| Qhov ntom | 2.7 g / cm³ | 7.7-7.85 g / cm³ | 7.1-7.3g / cm³ |

| Tensile zog | 100-400 MPa (txog 710 MPa rau qee cov alloys) | 340-1800 MPa | 150-400 MPa |

| Melting Point | 570-655 ° C | 1450-1520 ° C | 1150-1250 ° C |

| Thermal conductivity | 120-180 W/m·K | Nruab nrab | ~46 W/m·K |

| Hluav taws xob conductivity | Zoo | pluag | pluag |

| Machineability | Yooj yim | Nruab nrab | Zoo tab sis nkig |

| Corrosion Resistance | Zoo heev | Nruab nrab | pluag |

| Kev vibration Damping | Nruab nrab | Zoo | Zoo heev |

| Nqi | Tsawg rau kev tsim khoom loj | Siab | Nruab nrab |

- Cov txiaj ntsig:

- Ua cov duab complex nrog cov neeg siab.

- Txuag lub zog vim qhov qis melting point.

- Resistant corrosion, yog li nws kav ntev dua sab nraum zoov.

- Zoo rau cov khoom ntim siab.

- Kev txwv:

- Tsis muaj zog li steel.

- Nws tuaj yeem ua nkig hauv qee cov alloys.

- Yuav tsum tau ceev faj tswj kom tsis txhob muaj qhov tsis xws luag xws li porosity.

Kev txheeb cais qhia tau hais tias qhov zoo ntawm aluminium yaj thiab qhov muaj qhov tsis xws luag muaj qhov cuam tshuam loj rau lub zog thiab toughness. Cov kws tshaj lij siv cov kev ntsuam xyuas tshwj xeeb thiab software los xyuas thiab txhim kho kev ua haujlwm zoo.

Copper Casting Khoom

Cov khoom siv tooj liab yog paub zoo rau nws cov hluav taws xob thiab thermal conductivity. Cov neeg siv tooj liab castings hauv cov khoom siv hluav taws xob, cov kav dej, thiab cov khoom zoo nkauj. Copper alloys, zoo li tooj liab thiab tooj dag, muaj zog ntxiv thiab zoo dua corrosion kuj.

| Alloy Qauv | Hluav taws xob conductivity (% IACS) | Microhardness (Vickers) | Yield zog (MPa) |

|---|---|---|---|

| EML-200 | 80% | Piv rau EMI-10 | 614 ± 35 |

| EMI-10 | 60% | Piv rau EML-200 | 625 ± 17 |

Cov kev kho mob zoo li kev sib sib zog nqus undercooling tuaj yeem txhawb nqa conductivity yam tsis muaj zog. Ntxiv cov khoom xws li zinc lossis tin tuaj yeem txhim kho kev hnav thiab ua haujlwm ntev. Copper castings ua haujlwm zoo nyob rau hauv ib puag ncig hnyav vim tias lawv tiv thaiv corrosion, tshwj xeeb tshaj yog thaum alloyed nrog lwm yam hlau.

Magnesium Casting Khoom

Magnesium casting khoom yog lub teeb tshaj plaws ntawm tag nrho cov qauv hlau. Nws yog zoo meej rau cov khoom uas yuav tsum muaj zog tab sis tsis hnyav, xws li hauv tsheb, dav hlau, thiab hluav taws xob. Magnesium alloys muaj lub zog-rau-qhov hnyav piv thiab yooj yim rau tshuab.

- Cov yam ntxwv tseem ceeb:

- Lub teeb hnyav heev, uas pab txuag roj hauv tsheb.

- Zoo nruj thiab castability.

- High tshwj xeeb lub zog, tshwj xeeb tshaj yog nyob rau hauv cam khwb cia alloys.

Cov kev sim sim qhia tau hais tias ntxiv qhov los yog cov duab tshwj xeeb tuaj yeem ua rau magnesium txawm sib dua yam tsis tau poob ntau lub zog. Txawm li cas los xij, magnesium tuaj yeem corrode yooj yim, yog li cov coatings lossis alloying ntsiab feem ntau siv los tiv thaiv nws.

Zinc Casting Khoom

Zinc casting khoom feem ntau yog siv rau me me, cov ncauj lus kom ntxaws. Nws yog ib qho yooj yim rau cam khwb cia thiab sau cov pwm zoo, ua kom zoo rau cov iav, cov khoom ua si, thiab khoom siv kho vajtse. Zinc alloys muab lub zog zoo thiab toughness rau lawv qhov hnyav.

- Qhov zoo:

- Zoo heev rau kev ua cov duab complex.

- Zoo corrosion kuj.

- Tsawg melting point txuag lub zog thaum casting.

- Kev sib tw:

- Tsis muaj zog li steel lossis aluminium.

- Nws tuaj yeem ua nkig dhau sijhawm, tshwj xeeb tshaj yog nyob rau hauv cov mob khaub thuas.

Zinc castings muaj nyob rau hauv kev lag luam tsheb thiab hluav taws xob vim tias lawv sib xyaw ua ke nrog cov nqi zoo.

Yas Casting Khoom

Cov khoom siv yas casting qhib ntau qhov kev xaiv tsim. Nws yog lub teeb yuag, tiv thaiv corrosion, thiab tuaj yeem ua rau yuav luag txhua yam duab. Cov neeg siv cov yas castings hauv cov khoom siv kho mob, cov khoom siv, thiab cov khoom siv tsheb.

- Mechanical Properties:

- Lub zog, nruj, thiab toughness nyob ntawm seb hom yas thiab nws ua li cas.

- Ntxiv cov fibers xws li carbon lossis iav tuaj yeem ua rau cov yas muaj zog dua.

| Khoom / Khoom | Woodcast® | Synthetic Casting Materials | Plaster ntawm Paris (PoP) |

|---|---|---|---|

| Compression zog | Siab | qis | Txhaum |

| Tensile zog | qis | Siab dua | Txhaum |

| Flexural zog (MPa) | 14.24 Nws | 12.93–18.96 dr hab | N/A |

| Dej tsis kam | Zoo | Ntau yam | pluag |

Yas castings tuaj yeem tuav dej thiab cua sov zoo, nyob ntawm cov khoom siv. Qee qhov tsis muaj tshuaj lom thiab nyab xeeb rau kev siv kho mob. Lwm tus yuav muaj cov tshuaj uas yuav tsum tau ua tib zoo tuav.

Ceramic Casting Khoom

Ceramic casting cov khoom sawv cev rau nws lub peev xwm los tswj qhov kub thiab txias. Ceramics yog tawv, hnav-resistant, thiab tsis xeb. Tib neeg siv lawv hauv electronics, aerospace, thiab txawm tias cov hniav nyiaj hniav kub.

- Thermal Properties:

- Nws tuaj yeem tiv taus kub txog 1300 ° C.

- Zoo heev rau rwb thaiv tsev thiab tshav kub shields.

- Resilient:

- Saj zawg zog ceramic fibers yuav siv tau nyob rau hauv reusable rwb thaiv tsev rau spacecraft.

- Advanced ceramics muab lub zog siab nrog cov thermal conductivity tsawg.

Cov kws tshawb fawb tau tsim cov khoom siv ceramic tshiab uas muaj zog thiab hloov tau, ua rau lawv zoo tagnrho rau qhov chaw huab cua zoo li qhov chaw lossis cov khoom siv high-tech.

Ceramic casting cov ntaub ntawv khaws lawv cov duab thiab lub zog txawm tias thaum tshav kub kub, uas ua rau lawv muaj txiaj ntsig rau ntau yam kev siv niaj hnub no.

Kev xaiv cov khoom siv casting zoo tsim cov khoom zoo, tus nqi, thiab kev ua haujlwm zoo. Cov kws tsim khoom sib piv cov txheej txheem casting thiab cov khoom siv cov ntxhuav thiab cov ntaub ntawv tshawb fawb tiag tiag kom phim txhua yam khoom siv rau nws qhov zoo tshaj plaws. Paub cov ntsiab lus no pab pawg tsim cov khoom zoo dua, txuag nyiaj, thiab zam kev ua yuam kev kim.

FAQ

Dab tsi yog qhov txawv ntawm ferrous thiab non-ferrous casting cov ntaub ntawv?

Cov khoom siv hlau muaj hlau. Cov ntaub ntawv tsis-ferrous tsis. Ferrous hom feem ntau hnyav dua thiab xeb sai dua. Hom non-ferrous tiv thaiv xeb thiab xav tias sib dua.

Vim li cas engineers xaiv aluminium rau casting?

Aluminium hnyav dua li hlau. Nws tiv taus xeb thiab cov duab yooj yim. Engineers nyiam nws rau tsheb qhov chaw, lub dav hlau ncej, thiab electronics.

Plastics thiab ceramics puas tuaj yeem tiv taus kub kub?

Ceramics ua haujlwm kub heev. Cov yas feem ntau yog yaj ntawm qhov kub thiab txias. Cov kws tsim khoom xaiv cov ceramics rau qhov cub lossis lub cav, thaum cov yas haum rau cov haujlwm txias.

Post lub sij hawm: Jun-17-2025