Kev piav qhia

Txhawm rau tsim cov khoom lag luam zoo tshaj plaws ntawm tus nqi qis tshaj nrog kev ua haujlwm siab tshaj plaws thiab kev ntseeg siab, koj yuav tsum xaiv cov khoom hnav uas zoo rau koj daim ntawv thov crushing tshwj xeeb. Cov yam tseem ceeb uas yuav tsum tau xav txog raws li hauv qab no:

1. Hom pob zeb lossis cov ntxhia pob zeb yuav raug crushed.

2. Cov khoom me me, cov ntsiab lus noo noo thiab Mohs hardness qib.

3. Cov khoom siv thiab lub neej ntawm cov tshuab tshuab ua ntej siv.

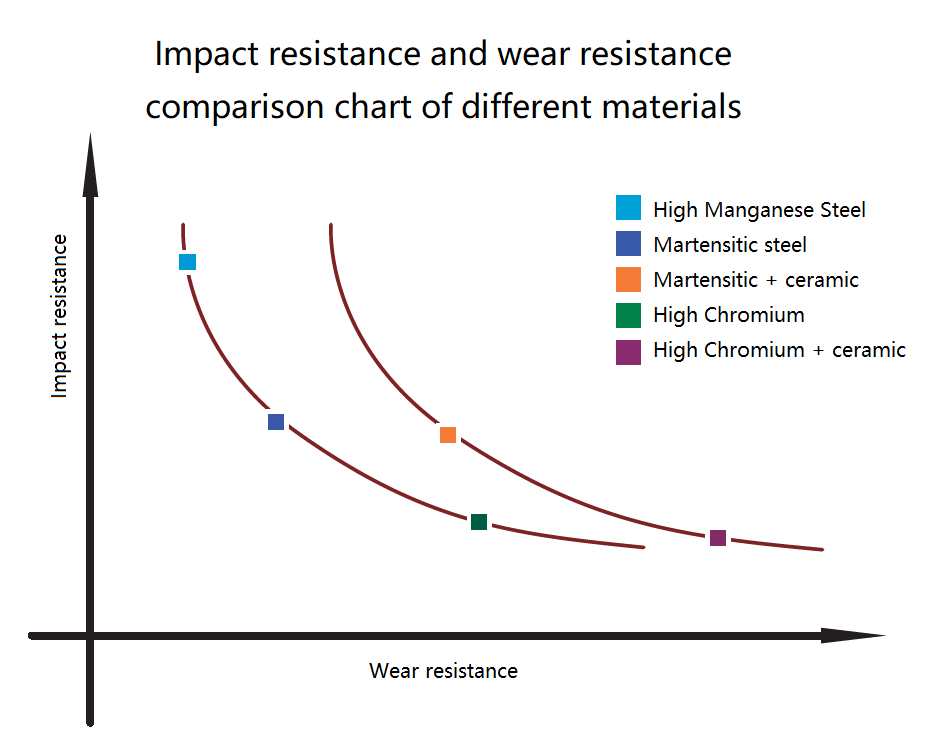

Feem ntau, qhov hnav tsis kam (lossis hardness) ntawm phab ntsa-mounted hlau hnav-resistant cov ntaub ntawv yuav inevitably txo nws cov kev cuam tshuam (los yog toughness). Cov txheej txheem ntawm embedding pottery nyob rau hauv cov khoom siv hlau matrix tuaj yeem ua rau nws hnav tsis kam tsis muaj kev cuam tshuam rau nws qhov kev cuam tshuam.

High Manganese hlau

High manganese steel yog cov khoom hnav-tiv taus nrog keeb kwm ntev thiab tau siv dav hauv kev cuam tshuam crushers. High manganese steel muaj qhov cuam tshuam zoo heev. Qhov hnav tsis kam yog feem ntau cuam tshuam nrog lub siab thiab cuam tshuam rau nws qhov chaw. Thaum muaj kev cuam tshuam loj heev, cov qauv austenite ntawm qhov chaw tuaj yeem ua rau HRC50 lossis siab dua.

High manganese steel phaj hammers feem ntau tsuas yog pom zoo rau thawj crushing nrog cov khoom loj pub particle loj thiab tsawg hardness.

Tshuaj muaj pes tsawg leeg ntawm siab manganese hlau

| Khoom siv | Tshuaj muaj pes tsawg leeg | Khoom vaj khoom tsev | ||||

| Mn% | Cr% | C% | Si% | Ib / cm | HB | |

| Mn 14 | 12-14 | 1.7-2.2 | 1.15-1.25 Nws | 0.3-0.6 hli | > 140 | 180-220 : kuv |

| Mn 15 | 14-16 | 1.7-2.2 | 1.15-1.30 Nws | 0.3-0.6 hli | > 140 | 180-220 : kuv |

| Mn 18 | 16-19 | 1.8-2.5 Nws | 1.15-1.30 Nws | 0.3-0.8 hli | > 140 | 190-240 : kuv |

| Mn 22 | 20-22 | 1.8-2.5 Nws | 1.10-1.40 Nws | 0.3-0.8 hli | > 140 | 190-240 : kuv |

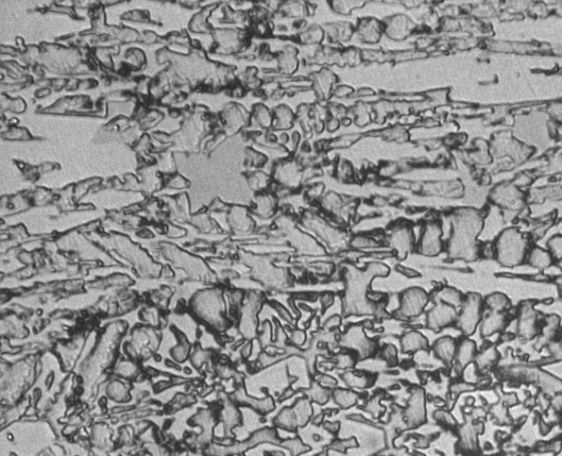

Microstructure ntawm high manganese hlau

Martensitic hlau

Martensite qauv yog tsim los ntawm kev ua kom txias sai ntawm cov pa roj carbon saturated siab. Cov pa roj carbon atoms tuaj yeem nthuav tawm ntawm martensite tsuas yog hauv cov txheej txheem txias sai tom qab kev kho cua sov. Martensitic steel muaj qhov hardness ntau dua li cov hlau manganese siab, tab sis nws cov kev cuam tshuam tsis zoo raug txo qis. Lub hardness ntawm martensitic hlau yog nyob nruab nrab ntawm HRC46-56. Raws li cov khoom no, martensitic steel tshuab tshuab feem ntau pom zoo rau crushing daim ntaub ntawv qhov twg kuj tsis tshua muaj kev cuam tshuam tab sis yuav tsum tau ntau dua hnav kuj.

Microstructure ntawm martensitic steel

High Chromium Dawb Hlau

Nyob rau hauv siab chromium dawb hlau, carbon yog ua ke nrog chromium nyob rau hauv daim ntawv ntawm chromium carbide. High chromium dawb hlau muaj zoo heev hnav tsis kam. Tom qab kev kho cua sov, nws qhov nyuaj tuaj yeem ncav cuag 60-64HRC, tab sis nws cov kev cuam tshuam tsis zoo yog txo qis. Piv nrog cov hlau manganese siab thiab martensitic steel, siab chromium cam khwb cia hlau muaj qhov hnav tsis kam, tab sis nws cov kev cuam tshuam kuj yog qhov qis tshaj.

Nyob rau hauv siab chromium dawb hlau, carbon yog ua ke nrog chromium nyob rau hauv daim ntawv ntawm chromium carbide. High chromium dawb hlau muaj zoo heev hnav tsis kam. Tom qab kev kho cua sov, nws qhov nyuaj tuaj yeem ncav cuag 60-64HRC, tab sis nws cov kev cuam tshuam tsis zoo yog txo qis. Piv nrog cov hlau manganese siab thiab martensitic steel, siab chromium cam khwb cia hlau muaj qhov hnav tsis kam, tab sis nws cov kev cuam tshuam kuj yog qhov qis tshaj.

Tshuaj muaj pes tsawg leeg ntawm siab chromium dawb hlau

| ASTM A532 Cov Lus Qhia Tshwj Xeeb | Kev piav qhia | C | Mn | Si | Ni | Cr | Mo | |

| I | A | Ni-Cr-Hc | 2.8-3.6 | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 Nws | 1.0 Max |

| I | B | Ni-Cr-Lc | 2.4-3.0 Nws | 2.0 Max | 0.8 Max | 3.3-5.0 | 1.4-4.0 Nws | 1.0 Max |

| I | C | Ni-Cr-GB | 2.5-3.7 Nws | 2.0 Max | 0.8 Max | 4.0 Max | 1.0-2.5 hli | 1.0 Max |

| I | D | Ni-HiCr | 2.5-3.6 | 2.0 Max | 2.0 Max | 4.5-7.0 Nws | 7.0-11.0 Nws | 1.5 Max |

| II | A | 12 Cr | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 Nws | 11.0-14.0 Nws | 3.0 Max |

| II | B | 15 CrMo | 2.0-3.3 | 2.0 Max | 1.5 Max | 0.80-1.20 Nws | 14.0-18.0 Nws | 3.0 Max |

| II | D | 20 CrMo | 2.8-3.3 | 2.0 Max | 1.0-2.2 | 0.80-1.20 Nws | 18.0-23.0 Nws | 3.0 Max |

| III | A | 25 Cr | 2.8-3.3 | 2.0 Max | 1.5 Max | 0.40-0.60 Nws | 23.0-30.0 Nws | 3.0 Max |

Microstructure ntawm High Chromium Dawb Hlau

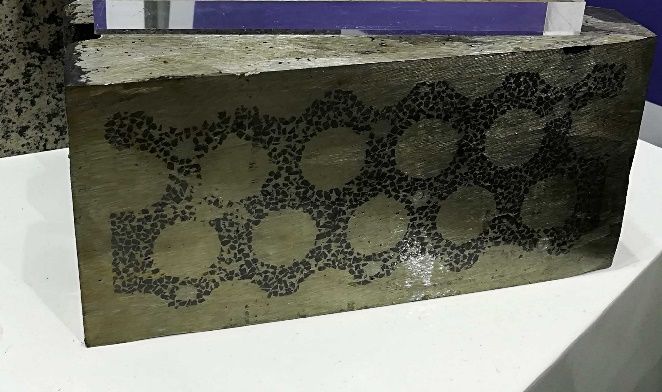

Ceramic-Metal Composite Material (CMC)

CMC yog cov khoom hnav-tiv taus uas sib xyaw ua ke zoo ntawm cov khoom siv hlau (martensitic steel lossis high-chromium cam khwb cia hlau) nrog cov hardness siab heev ntawm kev lag luam ceramics. Ceramic hais txog qhov loj me tshwj xeeb yog kho los tsim lub cev ntxeem tau ntawm cov khoom siv ceramic. Cov hlau molten penetrates tag nrho rau hauv lub interstices ntawm cov qauv ceramic thaum lub sij hawm casting thiab ua ke zoo nrog cov khoom siv hauv av.

Qhov kev tsim no tuaj yeem txhim kho qhov kev tiv thaiv kev hnav zoo ntawm lub ntsej muag ua haujlwm; Nyob rau tib lub sijhawm, lub cev tseem ceeb ntawm lub tshuab tshuab lossis rauj tseem ua los ntawm cov hlau los xyuas kom meej tias nws muaj kev nyab xeeb kev ua haujlwm, daws qhov tsis sib xws ntawm kev hnav tsis kam thiab kev cuam tshuam, thiab tuaj yeem hloov kho rau ntau yam kev ua haujlwm. Nws qhib qhov chaw tshiab rau kev xaiv cov khoom siv siab hnav rau feem ntau ntawm cov neeg siv, thiab tsim kom muaj txiaj ntsig zoo ntawm kev lag luam.

a. Martensitic Steel + Ceramic

Piv nrog rau cov tshuab martensitic zoo tib yam, lub tshuab martensitic ceramic tshuab rauj muaj zog dua ntawm nws qhov chaw hnav, tab sis qhov cuam tshuam tsis kam ntawm lub tshuab rauj yuav tsis txo qis. Hauv kev ua haujlwm, martensitic ceramic tshuab tshuab tuaj yeem hloov tau zoo rau daim ntawv thov thiab feem ntau tuaj yeem tau txais ze li 2 zaug lossis ntev dua kev pabcuam.

b.High Chromium Dawb Hlau + Ceramic

Txawm hais tias zoo tib yam high-chromium hlau tshuab twb muaj siab hnav tsis kam, thaum crushing cov ntaub ntawv uas siab heev hardness, xws li granite, ntau hnav-resistant tshuab tuav feem ntau yog siv los mus ntev lawv lub neej ua hauj lwm. Nyob rau hauv cov ntaub ntawv no, ib tug high-chromium cam khwb cia hlau nrog inserted ceramic tshuab yog ib tug zoo dua tov. Vim yog embedded ntawm ceramics, lub hardness ntawm hnav nto ntawm lub tshuab rauj yog ntxiv, thiab nws hnav tsis kam yog ho txhim kho, feem ntau 2 zaug los yog ntev kev pab cuam lub neej tshaj li ib txwm high chromium dawb hlau.

Qhov zoo ntawm Ceramic-Metal Composite Material (CMC)

(1) Nyuaj tab sis tsis nkig, tawv thiab hnav-tiv taus, ua tiav qhov sib npaug ntawm kev hnav tsis kam thiab siab toughness;

(2) Lub hardness ceramic yog 2100HV, thiab hnav tsis kam tuaj yeem ncav cuag 3 mus rau 4 npaug ntawm cov khoom siv zoo tib yam;

(3) Tus kheej lub tswv yim tsim, tsim nyog hnav kab ntau dua;

(4) Lub neej ua haujlwm ntev thiab cov txiaj ntsig kev lag luam siab.

Khoom Parameter

| Tshuab Hom | Tshuab qauv |

| Metso | LT-NP 1007 |

| LT-NP 1110 | |

| SIB 1213 | |

| LT-NP 1315/1415 | |

| LT-NP 1520/1620 | |

| Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 AWV 139 | |

| 1320 HAZ 1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ 814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ 565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ 815 HAZ 814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | QI341 (QI240) |

| QI441 (QI440) | |

| QI340 (I-C13) | |

| SIB 124 | |

| SIB 224 | |

| Kleemann | MR 110 EVO |

| MR 130 EVO | |

| MR 100 Z | |

| MR 122 Z | |

| Terex Pegson | XH250 (CR004-012-001) |

| XH320-new | |

| XH 320 | |

| 1412 (HWV 500) | |

| 428 HLB 4242 (300 siab) | |

| Powerscreen | Trackpactor 320 |

| Terex Finlay | Ib-100 |

| Ib-110 | |

| Ib-120 | |

| Ib-130 | |

| Ib-140 | |

| Rubblemaster | RM 60 |

| RM70 ua | |

| RM80 ua | |

| RM100 | |

| RM120 | |

| Tesab | RK-623 |

| RK-1012 | |

| Extec | C13 |

| Telsmith | ib 6060 |

| Keestrack | R3 |

| R5 | |

| McCloskey | kuv 44 |

| kuv 54 | |

| Lippmann | 4248 ib |

| Eagle | 1400 |

| 1200 | |

| Striker | 907 ib |

| 1112/1312-100 hli | |

| 1112/1312-120mm | |

| 1315 ib | |

| Kumbee | Tsis muaj 1 |

| Tsis muaj 2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM / Henan Liming / Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PW-1214 | |

| PW-1315 |