Kev tshuaj xyuas tsis tu ncua ntawmcrusher qhov chaw, suav nrogpuab tsaig crusher qhov chawthiabcone crusher spare qhov chaw, ua lub luag haujlwm tseem ceeb hauv kev ua kom pom kev ua tau zoo thiab kev ntseeg tau. Kev tshawb fawb qhia tiaskev tu cov khoom siv tsis txauszoo li covgyratory crushertuaj yeem ua rau kev ua tsis tiav ntxov, nrog rau feem pua ntawm cov teeb meem tseem ceeb rov qab mus rau qhov tsis muaj kev tshuaj xyuas.Cov khoom tseem ceeb los tshuaj xyuas muaj xws li hydraulic zog units, roj kub, thiab bearing tej yam kev mob. Kev saib xyuas cov ntsiab lus tsis tu ncua tsis yog tsuas yog tiv thaiv tus nqi poob qis xwb tab sis kuj txhim kho cov khoom siv tag nrho. Piv txwv li,raws sij hawm liner hloovnyob rau hauv crushers tuaj yeem tiv thaiv kev ua haujlwm poob, thaum kawg txuas ntxiv kev pabcuam lub neej ntawm qhov tseem ceeb, tshwj xeeb tshaj yog cov tsim los ntawmhigh manganese hlau casting.

Ntsiab Cai

- Kev tshuaj xyuas tsis tu ncua ntawm crusher qhov chaw yog qhov tseem ceeb rau kev ua haujlwm zoo thiab kev nyab xeeb. Tsom ntsoov rau cov khoom hnav, cov ntsiab lus lubrication, kev sib dhos, cov khoom siv hluav taws xob, thiabstructural kev ncaj ncees.

- Ua raws li lub sijhawm saib xyuas nruj. Ua txhua hnub kev kuaj xyuas cov bolts xoob thiab lubrication, kuaj pom txhua lub limtiam, thiab kev ntsuas txhua lub hlis.

- Saib xyuas cov cim ntawm kev hnav, xws li kev co ntau dhau, suab nrov, thiab pom cov kab nrib pleb. Kev tshawb pom ntxov tiv thaiv kev ua tsis tau tiav thiab kev poob qis.

- Sivcov ntaub ntawv zoo rau hnav qhov chawlos txhim kho durability. Kev tshuaj xyuas tsis tu ncua pab txheeb xyuas thaum hloov pauv tsim nyog, txuas ntxiv lub neej kev pabcuam ntawm cov khoom tseem ceeb.

- Muab qhov tseem ceeb ntawm kev nyab xeeb hluav taws xob thaum kuaj xyuas. Tshawb xyuas kev sib txuas kom ruaj ntseg thiab xyuas kom cov xaim hauv av tsis zoo los tiv thaiv hluav taws thiab ua kom muaj kev nyab xeeb.

Hnav Khaub Ncaws

Hnav cov khoom yog cov khoom tseem ceebnyob rau hauv tej crusher. Lawv muaj kev hnav thiab tsim kua muag thaum ua haujlwm. Kev tshuaj xyuas tsis tu ncua ntawm cov khoom no pab tswj kev ua haujlwm zoo thiab tiv thaiv qhov ua tsis tau tiav. Cov khoom siv tseem ceeb suav nrogtsau lub puab tsaig phaj, movable lub puab tsaig phaj, thiab sab plhu daim hlau. Txhua yam ntawm cov khoom no ua lub luag haujlwm tseem ceeb hauv cov txheej txheem crushing.

Nov yog cov ntsiab lus tseem ceeb ntawm cov khoom hnav hauv cov crushers:

| Hom Hnav Part | Kev piav qhia |

|---|---|

| Lub puab tsaig crusher hnav qhov chaw | Xws li lub puab tsaig ruaj ruaj, lub puab tsaig txav tau lub puab tsaig, thiab cov phaj puab sab plhu. |

| Tsau lub puab tsaig phaj | Installs nyob rau hauv lub puab tsaig crusher lub cev; muaj nyob rau hauv ib-thooj thiab ob-txheej tsim. |

| Movable lub puab tsaig phaj | Installs nyob rau hauv lub puab tsaig txav; kuj muaj nyob rau hauv ib-thooj thiab ob-txheej tsim. |

| Cheeb daim hlau | Tiv thaiv sab ntawm lub puab tsaig crusher lub cev los ntawm kev puas tsuaj los ntawm cov pob zeb crushed. |

Kev tshuaj xyuas tsis tu ncua ntawm lub puab tsaig crusher qhov chawyuav tsum tshwm sim txhua 250 teev ua haujlwm. Ua raws li lub sijhawm saib xyuas nruj nrog kev kuaj xyuas txhua hnub, txhua lub limtiam, thiab txhua hli yog qhov tseem ceeb. Cov neeg ua haujlwm yuav tsum nrhiavcov cim ntawm kev hnav ntau dhau, xws li:

- Ntau dhau kev co lossis suab nrov

- Pom cov kab nrib pleb lossis kev puas tsuaj

- Thinning hnav daim hlau thiab liner

- Cov qauv hnav tsis sib xws

- Txo cov khoom dhau los lossis cov khoom loj

- Nquag clogging los yog cov khoom jams

- Kev siv hluav taws xob ntau ntxiv

- Cov teeb meem overheating los yog lubrication

Lub neej ntev ntawm manganese qhov chaw tuaj yeem sib txawv heev, xws li los ntawmrau lub lis piam mus rau rau xyoo, nyob ntawm lub pob zeb ua tiav. Xaivcov ntaub ntawv zooNws yog ib qho tseem ceeb rau kev hnav cov khoom kom tiv taus cov xwm txheej hnyav. Cov ntaub ntawv hwm zoo txhawb kev tiv thaiv kev puas tsuaj, cuam tshuam, thiab hnav, ua rau lub neej ua haujlwm ntev. Kev tshuaj xyuas tsis tu ncua pab txheeb xyuas cov qauv hnav thiab txiav txim siab thaum twg yuav tsum tau hloov pauv.

Kev uakev xaiv zoo thiab kev tshuaj xyuas tsis tu ncuamaximizes kev ua tau zoo thiab durability. Kev saib xyuas kom zoo thiab kev ua haujlwm kom zoo yog qhov tseem ceeb rau kev siv nyiaj. Kev cob qhia tus neeg ua haujlwm kuj tseem txhawb nqa kev ua haujlwm tag nrho ntawm cov khoom hnav.

Lubrication Points

Kev lubrication kom zoo yog qhov tseem ceeb rau kev ua haujlwm zoo ntawm crusher qhov chaw. Kev tshuaj xyuas cov ntsiab lus lubrication tsis tu ncua tiv thaiv kev ua haujlwm tsis zoo thiab ua rau lub neej ntev ntawm cov khoom tseem ceeb. Txhua lub lubrication point muaj cov kev cai tshwj xeeb uas cov neeg ua haujlwm yuav tsum ua raws li kom muaj kev ua tau zoo.

Nov yog qee cov ntsiab lus tseem ceeb lubrication thiab lawvpom zoo lubricants:

| Lubrication Point | Pom zoo Lubricant | Sau ntawv |

|---|---|---|

| Eccentric Ncej Bearings | Jet-Lube Jet-Plex EP™ Roj Roj | Yuav tsum tau mechanically ruaj khov roj rau poob siab loading thiab vibration. |

| Pitman Bearings | Jet-Lube Jet-Plex EP™ Roj Roj | hnyav hnyav; roj yuav tsum muaj kev sib xws. |

| Dynamic Suspension Ncej | Nroj tsuag roj | Lubricated yam tsis muaj roj rov qab; xav tau daim ntawv thov tsis tu ncua. |

| Thrust phaj luj tshib | Cov roj tuab | Xav tau lubrication txhua 3-4 teev; txawv ntawm lwm cov ntsiab lus. |

| Lub puab tsaig me-hom Bearing | Roj khob thiab lubricating roj | Yuav siv tau ib zaug txhua 30-40 feeb. |

Cov neeg ua haujlwm yuav tsum teem sijhawmkev pabcuam txhua hnub thiab lubrication. Lawv yuav tsum kuaj xyuas cov chaw tsim khoom tshwj xeeb rau txhua yam khoom siv. Kev ua raws li kev tswj hwm kev kis kab mob kuj tseem ceeb heev. Kev tsis saib xyuas cov kev soj ntsuam no tuaj yeem ua rauqhov tshwm sim loj heev. Piv txwv li,ntxov ntxov bearing tsis ua hauj lwmtej zaum yuav tshwm sim vim tsis txaus lubrication. Tsis tas li ntawd, cov teeb meem zoo li lub tshuab nqus pa tuaj yeem tso cov plua plav mus rau hauv cov roj chamber, ua rau muaj teeb meem ntxiv.

Kev siv hom lubricant zoo yog qhov tseem ceeb. Cov neeg ua haujlwm yuav tsum xav txog tej yam kev mob xws li ya raws thiab kub. Xaiv cov roj nplua nyeem nrog cov dej tsis muaj dej tsis zoo thiab muaj kev tiv thaiv corrosion yog qhov tseem ceeb rau qhov chaw ntub dej. Cov roj viscosity siab dua ua haujlwm zoo tshaj plaws rau kev siv qis qis, siab load.

Kev txheeb xyuas

Alignment checks yog qhov tseem ceeb rau kev tswj xyuas qhov ua tau zoo thiab lub neej ntev ntawm crusher qhov chaw. Kev sib raug zoo kom ua haujlwm tau zoo thiab txo qis hnav ntawm cov khoom. Kev tshuaj xyuas tsis tu ncua tuaj yeem tiv thaiv tus nqi poob qis thiab txhim kho kev ua haujlwm tag nrho. Nov yog qee qhov kev txheeb xyuas qhov tseem ceeb los txiav txim siab:

- Belt Alignment: Kev siv txoj hlua khi kom raug yog qhov tseem ceeb rau kev ua haujlwm zoo. Nws ua kom cov ntaub ntawv du thiab txo qis sijhawm.

- Leveling lub Crusher: Ua kom cov qib crusher yog qhov tseem ceeb rau kev taug qab siv txoj siv. Qhov no yog qhov tseem ceeb tshwj xeeb tshaj yog tom qab tsiv cov khoom siv.

- Idler Kev Kho Kom Zoo: Yog tias txoj siv sia khiav tawm, kev hloov kho rau idlers yog tsim nyog. Cov kev txav tshwj xeeb tuaj yeem kho cov teeb meem sib dhos.

- Siv cov Extensions: Sib npaug txuas ntxiv lossis thim rov qab yog qhov tseem ceeb rau kev tswj txoj siv tawv. Qhov no pab tiv thaiv slippage thiab hnav.

- Kev Kho Txoj Siv Tshiab: Cov hlua khi tshiab yuav xav tau ntau yam kev hloov kho thaum lawv ncab thiab nyob rau hauv qhov chaw.

Misalignment tuaj yeem ua rau muaj ntau yam tsis zoo. Cov lus hauv qab no qhia txog qhov muaj feem cuam tshuam ntawm misalignment ntawm cov khoom tsim tawm thiab cov cuab yeej siv tau ntev:

| Qhov tshwm sim | Kev piav qhia |

|---|---|

| Accelerated Hnav thiab tsim kua muag | Misalignment ua rau tsis muaj zog uas ua rau muaj kev sib txhuam thiab kev sib cuag ntawm cov khoom. Qhov no ua rau muaj kev degradation sai dua thiab kev saib xyuas ntau zaus. |

| Lub zog tsis muaj zog | Misaligned machinery xav tau lub zog ntau dua los ua haujlwm. Qhov no ua rau cov nqi ua haujlwm siab dua thiab txo qis kev ua haujlwm ntawm cov khoom tsim tawm. |

| Txo lub neej ntev | Nruam raug rau ntau dhau kev vibrations shortens lub neej expectancy ntawm machinery. Qhov no ua rau kom muaj feem cuam tshuam thiab poob sijhawm. |

| Kev Nyab Xeeb Kev Nyab Xeeb | Cov qib vibration siab tuaj yeem ua rau muaj kev puas tsuaj loj. Qhov no ua rau muaj kev pheej hmoo rau cov neeg ua haujlwm thiab ib puag ncig infrastructure. |

| Cov teeb meem kev tswj xyuas zoo | Cov txiaj ntsig tsis sib xws los ntawm cov khoom siv misaligned tuaj yeem ua rau cov khoom xa tuaj tsis zoo. Qhov no cuam tshuam tag nrho cov khoom zoo. |

Txhawm rau ua qhov kev kuaj xyuas kom zoo, cov neeg ua haujlwm tuaj yeem siv ntau yam cuab yeej thiab cov txheej txheem. Cov lus hauv qab no qhia txog cov khoom siv sib xws thiab lawv qhov tseem ceeb hauv kev txheeb xyuas kev sib raug zoo:

| Hom khoom siv | Qhov tseem ceeb ntawm kev txheeb xyuas kev sib tw |

|---|---|

| Turbines (gas, cua, chav) | Muaj peev xwm muaj kev hloov pauv kub ua rau muaj kev txav mus los hauv cov kav dej thiab cov hauv paus. |

| Cov Cua Txias Chillers | Aligned Cheebtsam yog raug rau qhov tsis xav txav vim yog compressor mounting. |

| Chilled Dej, Condenser Dej, thiab pub dej twj tso kua mis | Kev hloov kub tuaj yeem ua rau lub tshuab txav mus los, tshwj xeeb tshaj yog tias cov hauv paus tsis loj txaus. |

| Extruders | Qhov kub hloov pauv loj tuaj yeem ua rau lub tshuab txav mus rau lub sijhawm. |

| Rauj Mills, Crushers | Qhov xwm txheej ntawm kev ua haujlwm tuaj yeem ua rau tsis muaj kev txav mus los, txawm tias bolted. |

| Lwm Cov Tshuab | Muab cov txiaj ntsig zoo li tshuaj xyuas cov txuas txuas thiab cov ntsaws ruaj ruaj, thiab xyaum nrog cov cuab yeej sib dhos. |

Kev txheeb xyuas kev sib raug zoo yog qhov tseem ceeb rau kev tswj xyuas qhov ua tau zoo thiab kev nyab xeeb ntawm crusher qhov chaw. Kev siv lub sijhawm tshuaj xyuas niaj hnub tuaj yeem txhim kho cov cuab yeej ua haujlwm tau zoo thiab ua haujlwm ntev.

Hluav taws xob Cheebtsam

Cov khoom siv hluav taws xob ua si tseem ceeb heevlub luag haujlwm hauv kev ua haujlwm ntawm crushers. Kev tshuaj xyuas tsis tu ncua ntawm cov khoom no pab tiv thaiv kev ua tsis tiav thiab ua kom muaj kev nyab xeeb. Cov neeg ua haujlwm yuav tsum tsom mus rau ntau qhov chaw tseem ceeb thaum lawv kuaj xyuas.

Tej teeb meem hluav taws xobpom thaum lub sij hawm soj ntsuam crusher muaj xws li:

- Cov teeb meem hluav taws xob hluav taws xob, xws li qhov tsis muaj zog lossis tsis muaj zog.

- Faulty start keyboards los yog teeb meem nrog lub tswj vaj huam sib luag.

- Blown fuses lossis tripped circuit breakers.

- Ua kom muaj kev ruaj ntseg interlocks lossis nres thaum muaj xwm ceev.

- Faulty xaim lossis kev sib txuas.

- Sensor tsis ua hauj lwm los yog kev sib txuas lus yuam kev hauv automated systems.

- Software glitches los yog outdated firmware.

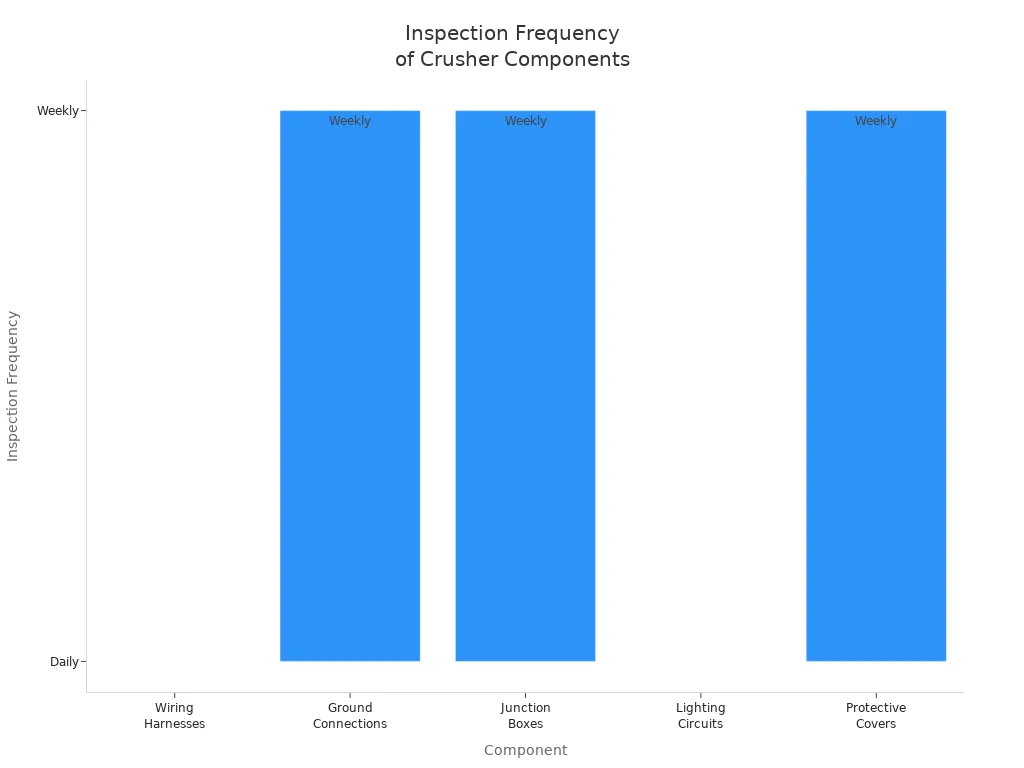

Txhawm rau ua raws li cov cai tswj kev nyab xeeb, cov neeg ua haujlwm yuav tsumtshuaj xyuas cov khoom siv hluav taws xob tsis tu ncua. Cov lus hauv qab no qhia txog qhovpom zoo tshuaj xyuas hom thiab zaus:

| Cheebtsam | Hom tshuaj ntsuam xyuas | Ntau zaus |

|---|---|---|

| Cov kab hluav taws xob | Visual/Physical | Txhua hnub |

| Kev sib txuas hauv av | Kev ntsuas ntsuas | Txhua lub lim tiam |

| Junction Boxes | Moisture Check | Txhua lub lim tiam |

| Teeb pom kev zoo Circuits | Function Test | Txhua hnub |

| Kev tiv thaiv npog | Tshawb xyuas kev ncaj ncees | Txhua lub lim tiam |

Kev tshuaj xyuas cov kab hluav taws xob thiab kev sib txuas yog qhov tseem ceeb. Cov neeg ua haujlwm yuav tsum:

- Xyuas kom tseeb tias kev sib txuas hluav taws xob muaj kev ruaj ntsegua ntej pib cov khoom siv.

- Tsis tu ncua xyuas cov kev sib txuas xoob lossis cov xov hlau frayedkom tsis txhob muaj hluav taws kub.

- Xyuas kom meej tias cov xov hlau hauv av, lub cev muaj zog plugs, thiab cov khoom siv hluav taws xob sib txuas muaj kev ruaj ntseg ua ntej cov khoom siv ua haujlwm.

Kev tsis saib xyuas cov kev tshuaj ntsuam no tuaj yeem ua rau muaj kev pheej hmoo loj.Cov khoom siv hluav taws xob yuam kev tuaj yeem ua rau hluav taws kub, ua rau nws tseem ceeb kom muaj peev xwm tua hluav taws ntawm qhov chaw. Kev tshuaj xyuas qhov muag tsis tu ncua pab kom muaj kev nyab xeeb thiab kev txhawb nqa cable zoo. Tsis tas li ntawd, cov chav tsev hluav taws xob yuav tsum nyob twj ywm qhuav thiab tsis muaj cov khoom siv hluav taws xob.

Los ntawm kev saib xyuas cov khoom siv hluav taws xob ua ntej, cov neeg ua haujlwm tuaj yeem txhim kho kev nyab xeeb thiab kev ua haujlwm ntawm lawv cov haujlwm crusher.

Kev ntseeg ruaj khov

Kev tuav lubstructural kev ncaj ncees ntawm crushersyog qhov tseem ceeb rau kev nyab xeeb thiab ua haujlwm tau zoo. Kev tshuaj xyuas tsis tu ncua pab txheeb xyuas cov teeb meem muaj peev xwm ua ntej lawv nce mus rau qhov kev puas tsuaj loj. Cov neeg ua haujlwm yuav tsum tsom mus rau ntau qhov kev kuaj xyuas tseem ceeb los xyuas kom meej cov qauv zoo ntawm lawv cov khoom siv.

Nov yogQhov tseem ceeb ntawm cov qauv kev ncaj ncees kuaj xyuas cov crushers:

| Kuaj Hom | Kev piav qhia |

|---|---|

| Bolt Torque Checks | Cov sij hawm niaj hnub rau kev kuaj xyuas thiab rov torquing cov txheej txheem tseem ceeb yog qhov tseem ceeb. |

| Kev tshuaj xyuas tawg | Kev tshuaj xyuas ib ntus rau cov kab plaub hau tawg, tshwj xeeb tshaj yog nyob ib puag ncig cov ntsiab lus kev ntxhov siab, yog qhov tseem ceeb. |

| Lubrication | Kev lubrication kom raug nrog hom thiab qib zoo tiv thaiv overheating thiab hnav. |

| Kev ntsuas vibration | Kev kuaj xyuas tsis tu ncua tuaj yeem pom cov cim qhia ntxov ntawm kev ua tsis tiav ua ntej lawv ua rau muaj kev puas tsuaj loj. |

Ib puag ncig yam xws li kev vibration thiab kub tuaj yeem cuam tshuam rau kev ncaj ncees ntawm cov khoom crusher.Variations nyob rau hauv qhov kub thiab txias loadsnyuaj structural dynamics, uas yuav ua rau tsis ua hauj lwm. Piv txwv li, kev ua haujlwm siab ceev tuaj yeem ua rau muaj kev vibration ntau dhau, ua rau kev puas tsuaj ntawm cov qauv. Kev lubrication kom raug yog qhov tseem ceeb los txo cov kev pheej hmoo no.

Cov teeb meem kev teeb tsa uas tau pom thaum kuaj xyuassuav nrog:

- Mechanical Failures

- Bearings overheating los yog hnav tawm ntxov ntxov.

- Cracks los yog tawg nyob rau hauv lub crusher ncej.

- Kev vibration thiab suab nrov

- Ntau dhau kev vibration lossis suab nrov thaum ua haujlwm.

- Hydraulic System Failures

- Cov dej ntws los yog tsis txaus siab.

Kev tshuaj xyuas tsis tu ncua thiab kev saib xyuas ntawm cov qauv kev ncaj ncees tuaj yeem tiv thaiv kev poob qis thiab txhim kho lub neej ntawm cov khoom crusher. Cov neeg ua haujlwm yuav tsum ua qhov tseem ceeb rau cov kev kuaj xyuas no kom muaj kev nyab xeeb thiab ua haujlwm tau zoo.

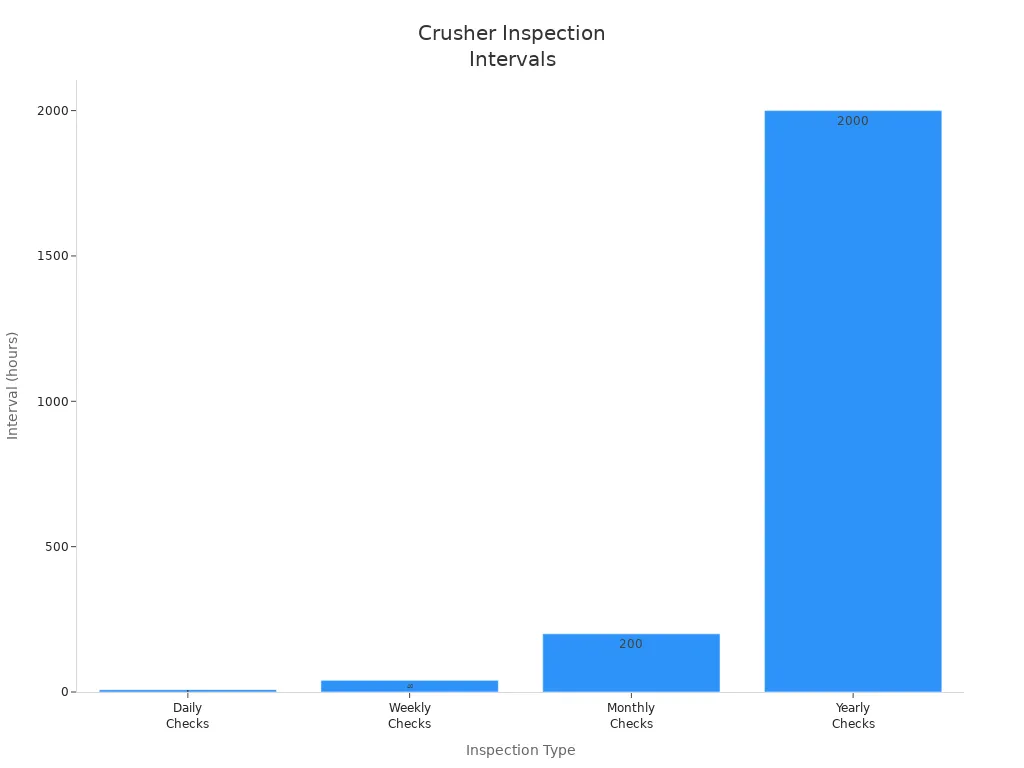

Kev tshuaj xyuas tsis tu ncua ntawm crusher qhov chaw yog qhov tseem ceeb rau kev tswj xyuas kev ua haujlwm zoo thiab kev nyab xeeb. Cov ntsiab lus tseem ceeb ntawm kev tshuaj xyuas muaj xws li:

- Kev tshuaj xyuas txhua hnub: Txheeb xyuas cov bolts xoob, tshuaj xyuas lub puab tsaig daim hlau, thiab lubricate qhov chaw txav.

- Kev Kho Txhua Lub Limtiam: Ua kev tshuaj xyuas qhov muag thiab xyuas cov hnab looj tes.

- Kev Kho Ib Hlis: Tshawb xyuas cov tshuab tshuab thiab roj qib.

- Kev Txhim Kho Txhua Xyoo: Disassemble thiab tshuaj xyuas qhov hnav kom puas.

Ua raws li lub sijhawm tshuaj xyuas niaj hnub ua rau txo qis sijhawm thiab kho cov nqi kho mob. Kev saib xyuas tsis saib xyuas tuaj yeem ua raukev tawg ntau dhau, raug nqi ze li $50,000 ib teev. Los ntawm qhov tseem ceeb ntawm kev tshuaj xyuas tsis tu ncua, cov neeg ua haujlwm tuaj yeem txhim kho cov cuab yeej siv tau ntev thiab ua haujlwm tau zoo.

FAQ

Dab tsi yog qhov tseem ceeb tshaj plaws los tshuaj xyuas ntawm lub crusher?

Cov neeg ua haujlwm yuav tsum tsis tu ncuatshuaj xyuas qhov hnav, lubrication cov ntsiab lus, kev sib dhos, cov khoom siv hluav taws xob, thiab kev ua haujlwm ruaj khov. Cov cheeb tsam no cuam tshuam rau lub crusher kev ua tau zoo thiab lub neej ntev.

Ntev npaum li cas kuv yuav tsum ua kev tshuaj xyuas ntawm kuv lub crusher?

Kev tshuaj xyuas txhua hnub yog qhov tseem ceeb rau xoob bolts thiab lubrication. Kev kuaj xyuas txhua lub limtiam yuav tsum suav nrog kev tshuaj xyuas qhov muag, thaum kev saib xyuas txhua hli tsom rau cov tshuab tshuab. Kev kho dua tshiab txhua xyoo yog qhov tseem ceeb rau kev ntsuam xyuas zoo.

Dab tsi cov cim qhia tias hnav ntawm crusher qhov chaw?

Cov cim ntawm kev hnav muaj xws li kev vibration ntau dhau, suab nrov, pom cov kab nrib pleb, thinning hnav daim hlau, thiab cov qauv hnav tsis sib xws. Cov neeg ua haujlwm yuav tsum saib xyuas cov ntsuas no txhawm rau tiv thaiv qhov ua tsis tau tiav.

Vim li cas lubrication kom zoo tseem ceeb rau crushers?

lubrication kom raugtxo kev sib txhuam thiab hnav ntawm cov khoom txav. Nws tiv thaiv overheating thiab ncua lub neej ntawm cov khoom tseem ceeb, ua kom muaj kev ua haujlwm zoo thiab txo qis qis qis.

Kuv tuaj yeem ua kom muaj kev nyab xeeb hluav taws xob li cas thaum kuaj xyuas?

Tshawb xyuas kev sib txuas hluav taws xob kom ruaj ntseg thiab xyuas cov xov hlau frayed. Xyuas kom cov hauv av xaim thiab fais fab cable txuas tsis zoo lawm. Kev kuaj pom tsis tu ncua pab tswj kev nyab xeeb thiab tiv thaiv hluav taws kub.

Post lub sij hawm: Oct-17-2025